-

Fiber Ends

-

Fiber Arrays

-

Ferrule Assemblies

-

Pigtails

-

Molded Lenses

-

Laser Diodes

-

Laser Bars

-

TO Caps

-

Glass / Metal Assemblies

-

Isolaters

-

Fiber Optic Faceplates

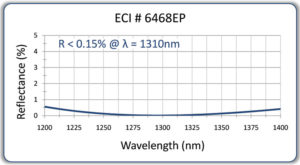

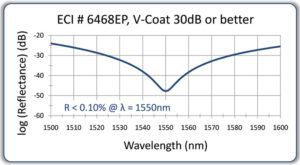

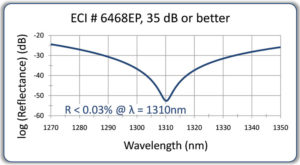

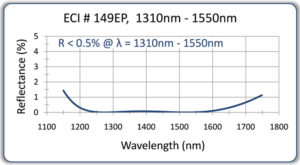

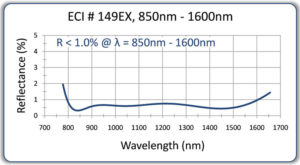

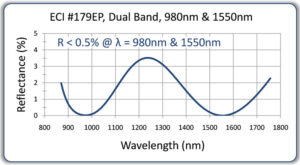

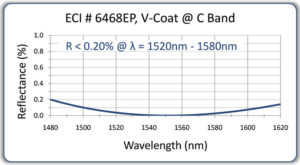

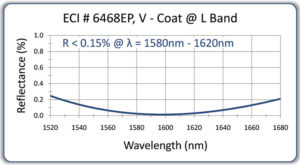

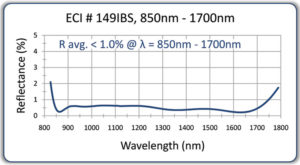

Preparation and coating processes are performed in a clean room environment. Process temperatures below 50°C minimize out-gassing from epoxies and cladding materials. Designs include super low, narrow band laser wavelengths, C-Band, L-Band and dual wavelength coatings.

Coatings are designed for components whose devices must pass extended humidity and temperature cycling!

Custom coating designs are available.

Contact our design team to discuss your specific AR Coatings for Fibers and FiberOptic Devices application!