Custom and standard anti-reflection coatings from super low narrow band to extended high performance broadband are available for deposition on all types of glass substrates including:

-

Fused Silica

-

Precision Glass Optics

-

Molded Glass Elements

-

High Expansion Glasses

-

Gradient Index Glass

-

CaF2

-

BaF2

-

High Stain Glasses

-

Ball lenses

-

Ultra Thin Wafers

-

High Index Glasses

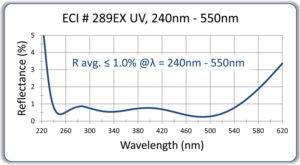

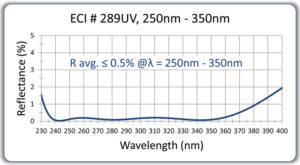

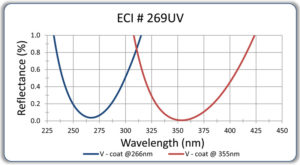

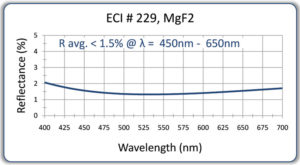

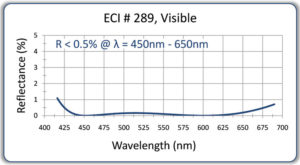

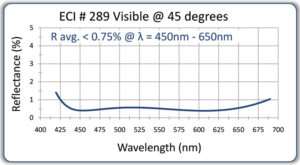

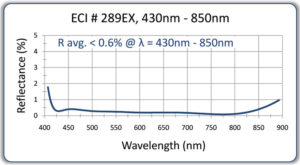

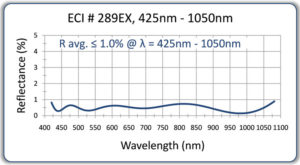

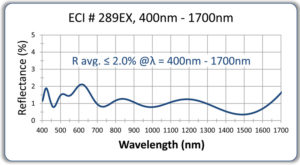

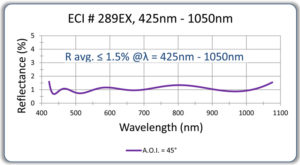

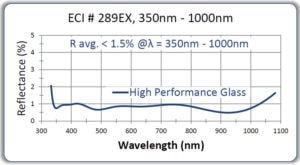

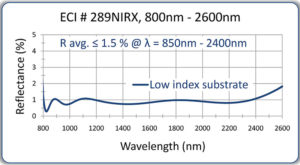

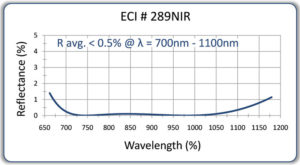

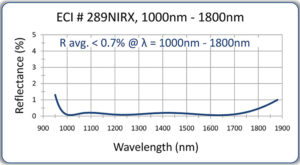

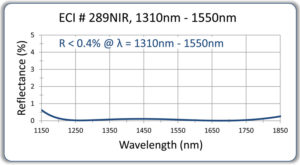

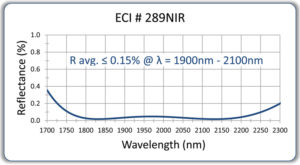

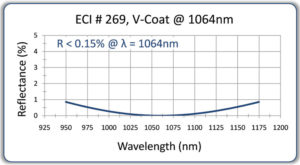

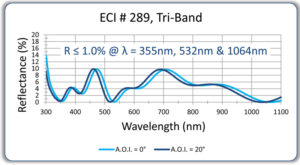

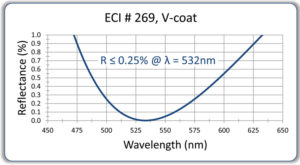

ECI‘s coating designs can be optimized for maximum performance from the 200nm – 2500nm wavelength region. Specify your particular wavelength range, angle of incidence, substrate index of refraction, incident medium and polarization requirements to ensure maximum transmission for your system. Designs include V-coats, broadband, super broadband, dual band and narrow band coatings.

Glass Anti-Reflection coatings are utilized in a variety of applications. It is very common for these coatings to be used in laser applications. In such cases, they will need to meet or exceed certain LDT ( Laser Damage Threshold ) requirements. ECI primarily uses Ion Beam Sputtering ( IBS ) or Electron Beam ( E-Beam ) to deposit AR coatings that must withstand high power lasers. ECI deposits High Power Glass AR coatings on various substrates including: Glass/Fused Silica windows, lenses and wafers, Fiber optic cables and assemblies, LBO, BBO, KTP, TGG, GGG, BiG, and Silicon wafers.

Designs are RoHS compliant.

Contact our design team to discuss your AR Coating needs for your Glass application!