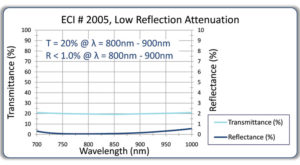

Typical designs absorb and reflect the unwanted energy but ECI offers special low reflection attenuation films that have very low first and/or second surface reflection. Transmission values can be tailored to your system requirements. These thin film designs are suitable for deposition onto molded polymer optics, glass/metal TO can assemblies, fiber ends and glass fabricated to your requirements. These coatings are commonly used on components in front of lasers or detectors to reduce energy levels to safe or acceptable levels while minimizing back reflection. These coatings can be designed for most any transmission value and typically have back reflection greater than 20 decibels. Custom designs are available if a specific amount of back-reflection is desired.

All coatings are optimized for angle of incidence, wavelength region, incident medium and front or back surface use.

These films are deposited at low temperatures, below 50°C, to minimize process contamination concerns from epoxies, cladding or polymer optics. Our high energy deposition process produces very dense and stable films that will survive typical industry environmental testing.

ECI has experience fixturing fiberoptic components for low or high volume production requirements. We will recommend packaging methods that minimize handling and reduce cost. Contact one of our sales engineers to discuss your particular needs.

ECI also offers neutral density coatings for balanced attenuation across the visible wavelength region.

We can supply these filters complete to your exact size requirements.

Contact our design team to discuss your specific Attenuation Coatings application!