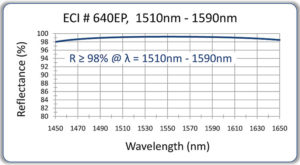

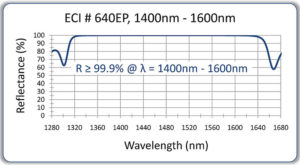

ECI’s thin film coatings are comprised of all-dielectric materials designed to meet extended humidity and temperature cycling environments. ECI’s custom coatings are designed to your requirements including: bandwidth, percent reflection, angle of incidence, polarization state and incident medium. Typical performance is a minimum of 90% to greater than 99.5% at the desired spectral range.

ECI has the experience to fixture, clean, coat and inspect Fiber Optic Devices. Preparation and coating processes are performed in a clean room environment. Process temperatures below 60°C minimize out-gassing from epoxies and cladding materials.

ECI’s coatings meet the durability and environmental requirements of MIL-C-48497.

Contact our design team to discuss your specific Dielectric Mirror coatings for Fiber Optic Devices application!